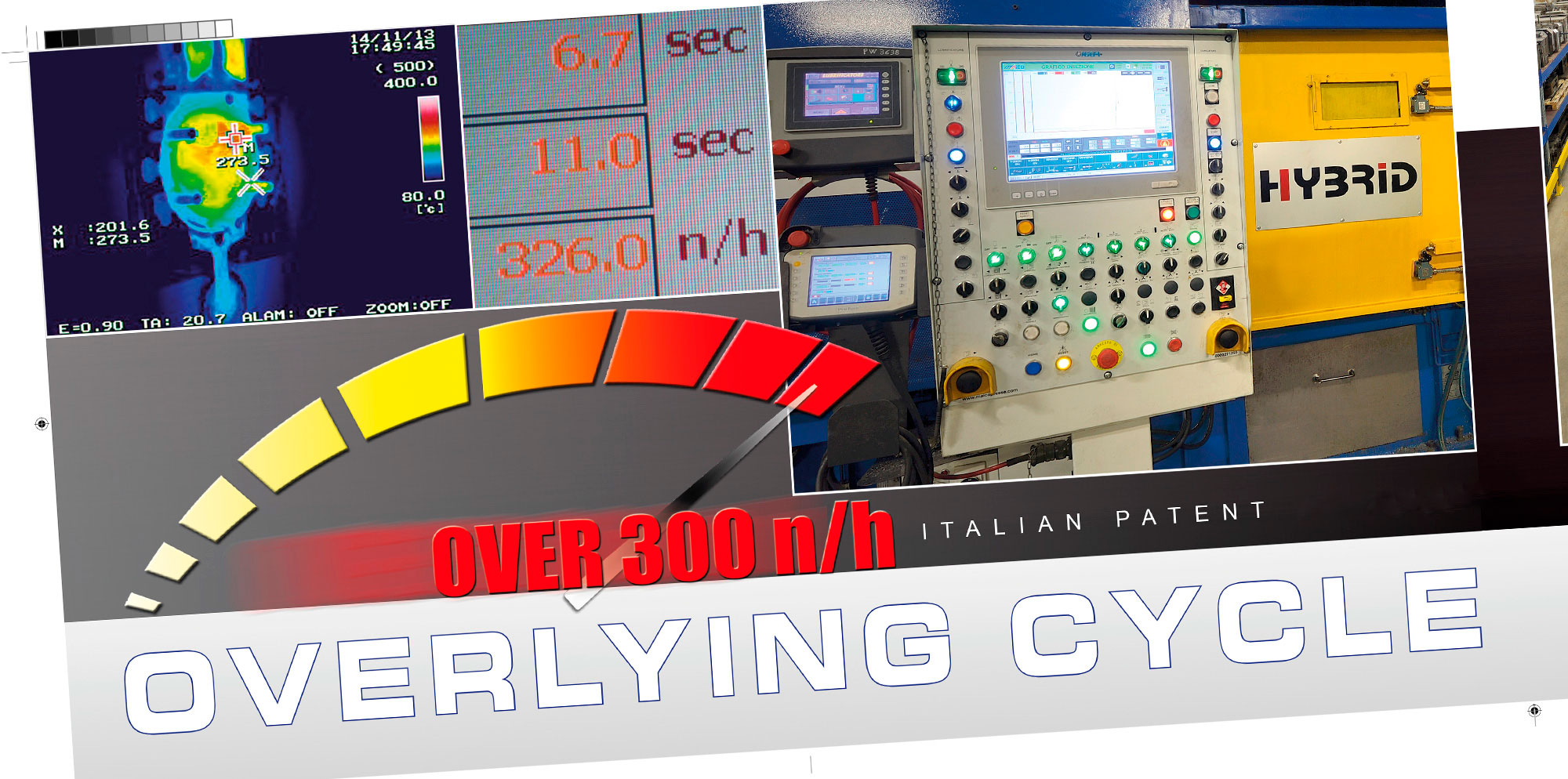

OVERLYING CYCLE

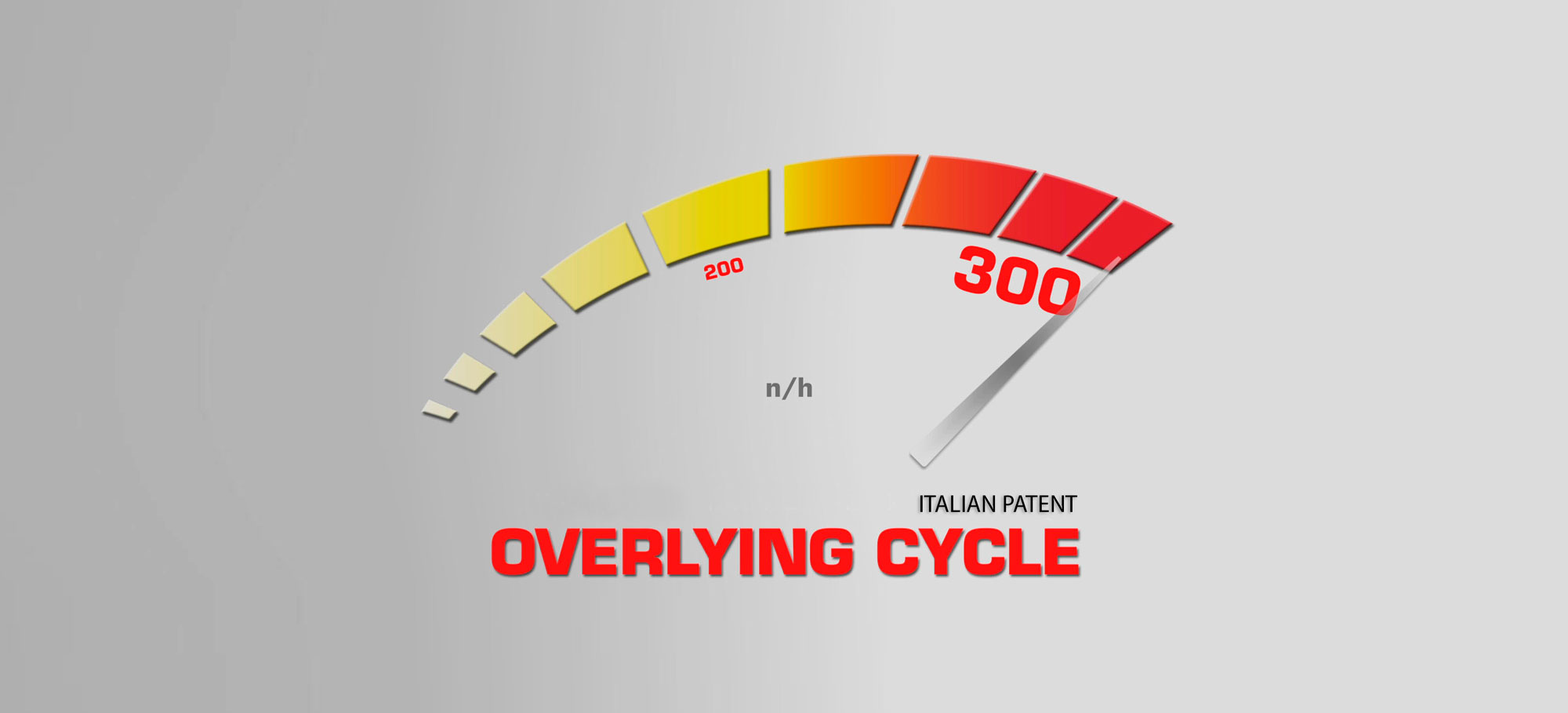

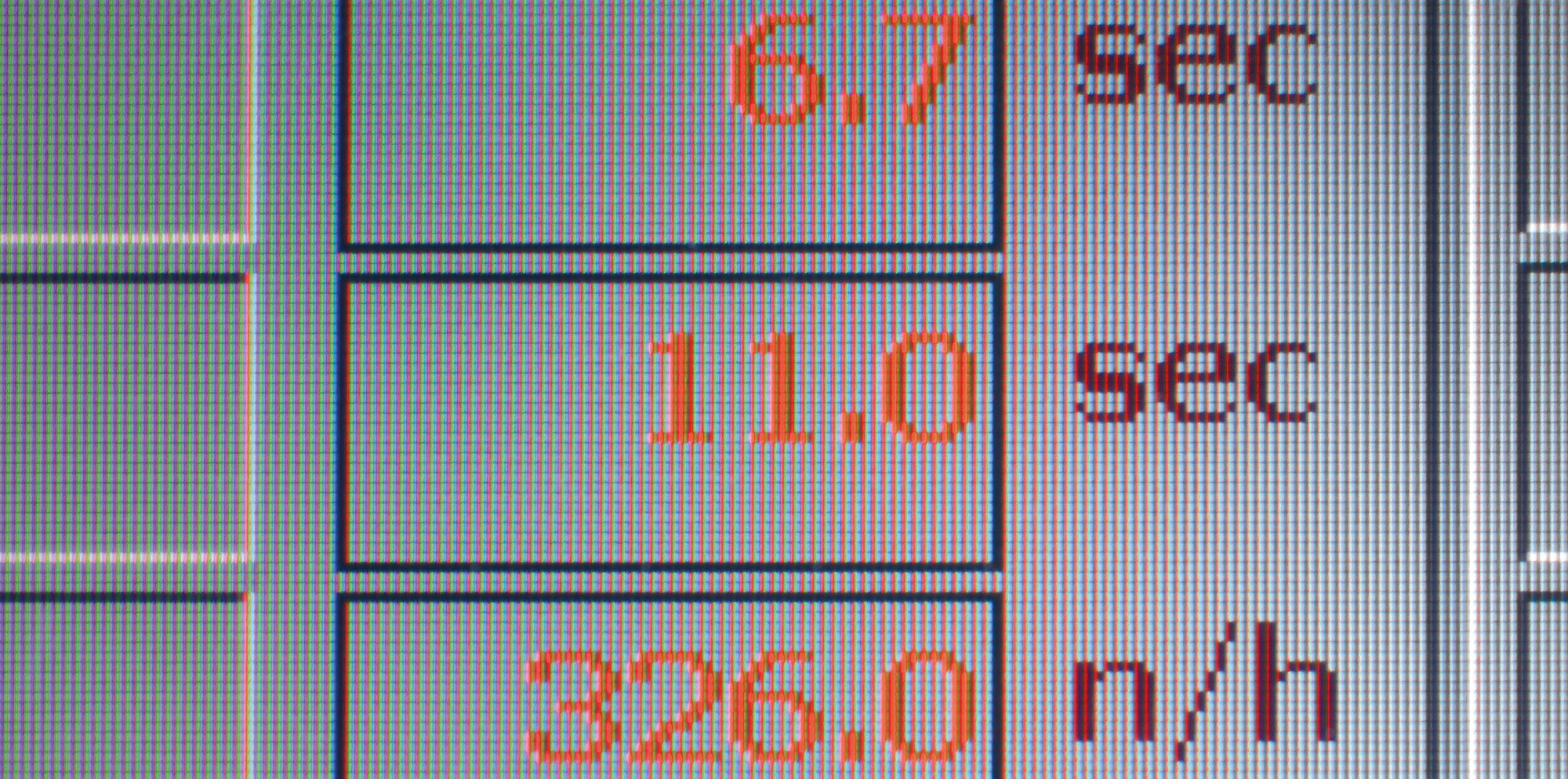

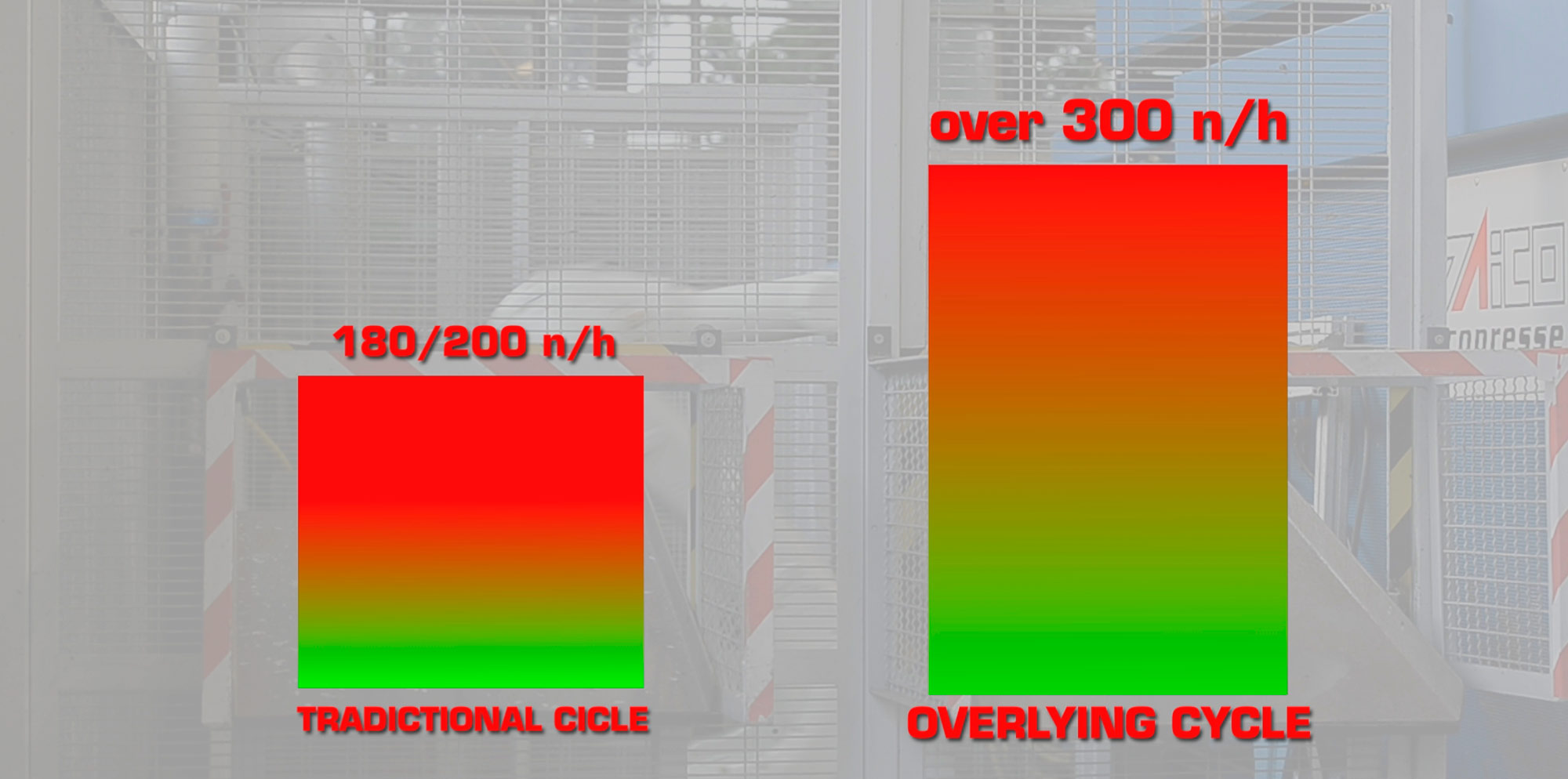

The overlying cycle, an exclusive patent owned by Eurofusioni Nironi, is based on the principle of overlying phases, employing a modern electric press that allows us to achieve over 300 cycles/hour with energy consumption levels below 6.5 kw/hour, thus reaching the lowest industrial costs per product unit ever seen and a higher die-casting quality than what has been traditionally achieved, thanks to the cycle’s ability to use molten alloys at temperatures up to 20°C lower than the norm, which reduces the quantity of oxides and dissolved gases in the molten alloy.

This technology is ideal for smaller die-cast components. It has a low impact on production costs and does not require vast amounts of space to be installed. Highly qualified personnel maintain it and its quality levels are constantly monitored by sophisticated instruments.

Another distinctive trait of our company, besides designing the molds in-house to best exploit our technology, is how we continuously check and treat the molten alloy by constantly measuring the alloy element values in the molten bath using a quantometer, and by applying continuous degassing treatments, thus achieving very high and constant density values (under water weight check of vacuum-solidified samples).

In recent years, we have also had great success with our work in mechanical processing of castings ; this is now on the list of consolidated finishing processes that we offer (cutting, beveling, milling, grinding and double-loading frame sandblasting, tumble finishing, polishing, liquid and powder painting, assembly).

We plan to pool future resources to further invest in overlying cycle technology, expanding our existing plant and continuing to refine and where possible improve our technology, which we believe represents the future of our industry.